Pharmaceutical manufacturing

Standard Operating Procedure (SOP) for Change Control Management for Batch Records

Standard Operating Procedure (SOP) for Change Control Management for Batch Records Read More »

Standard Operating Procedure (SOP) for Batch Record Reconciliation

Standard Operating Procedure (SOP) for Batch Record Reconciliation Read More »

Standard Operating Procedure (SOP) on Data Integrity and ALCOA Principles in Batch Record Management

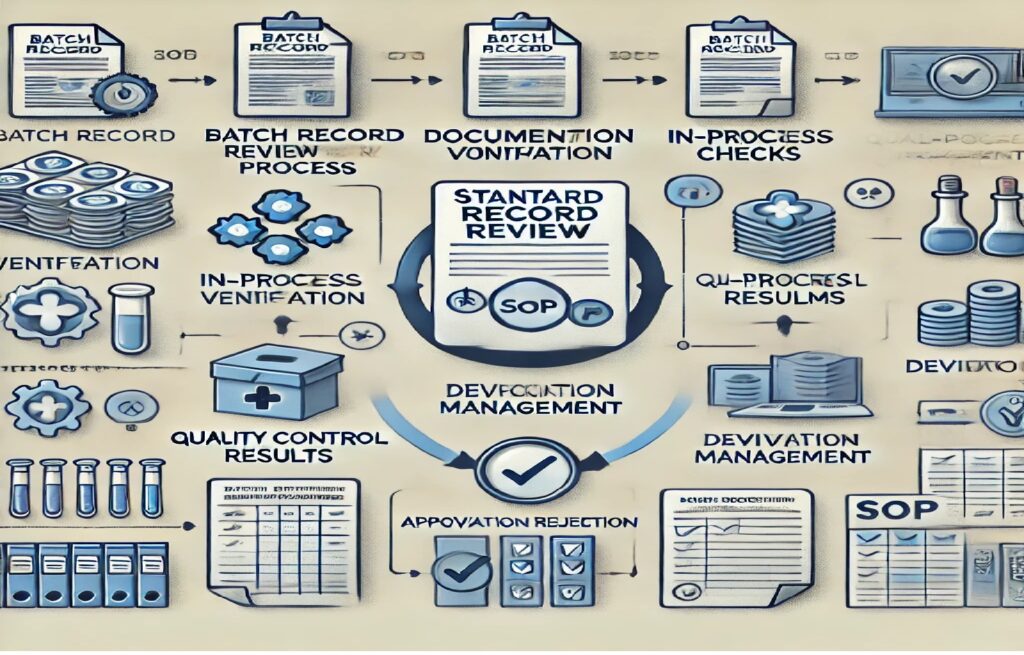

Standard Operating Procedure (SOP) for Batch Record Review

Standard Operating Procedure (SOP) for Batch Record Review Read More »

Standard Operating Procedure (SOP) on Batch Record Completion

Standard Operating Procedure (SOP) on Batch Record Completion Read More »

Standard Operating Procedure (SOP) for Batch Record Issuance and Control

Standard Operating Procedure (SOP) for Batch Record Issuance and Control Read More »

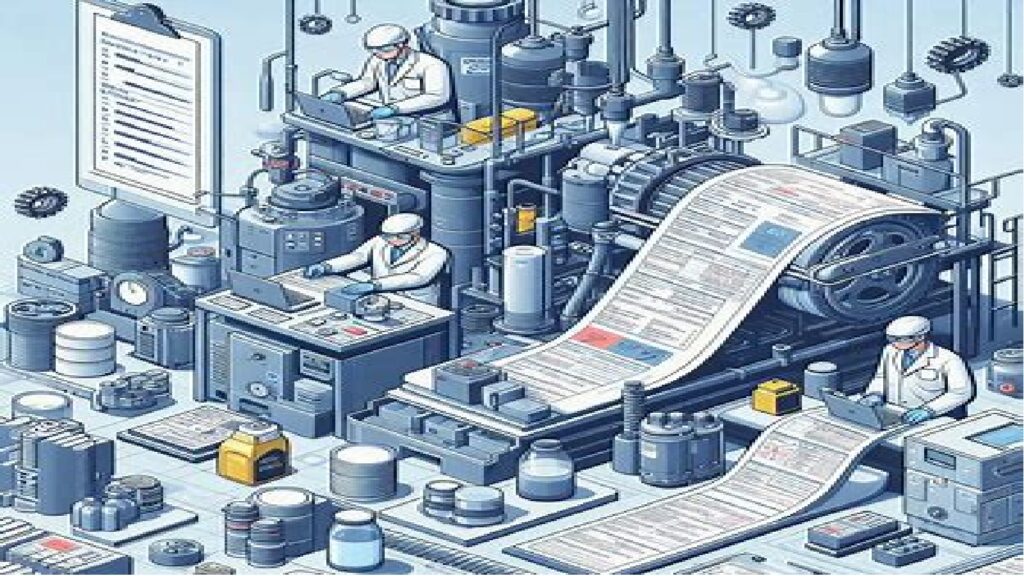

Standard Operating Procedure (SOP) for Batch Record Preparation

Standard Operating Procedure (SOP) for Batch Record Preparation Read More »

Standard Operating Procedure (SOP) for Out-of-Specification (OOS) Investigations

Standard Operating Procedure (SOP) for Out-of-Specification (OOS) Investigations Read More »

QA in Pharma: Crucial Interview Queries

QA in Pharma: Crucial Interview Queries Read More »