Quality control

1. Automation in Pharmaceutical Manufacturing 1.1. Introduction to Automation in Pharmaceuticals 1.1.1 What is Automation? Automation involves using machines, control systems, and software to perform tasks with minimal human intervention. In pharmaceutical manufacturing, it encompasses everything from production lines to quality control. 1.1.2 Why is Automation Important? Pharmaceutical manufacturing demands high accuracy and compliance with […]

“Navigating Challenges: Effective Strategies for Managing Risk in Pharmaceutical Manufacturing”

1. Understanding Risks in Pharmaceutical Manufacturing 1.1. The Importance of Risk Understanding 1.1.1 Why Risk Awareness is Critical 1.1.2 Role of Risk Understanding in Decision-Making 1.2. Types of Risks in Pharmaceutical Manufacturing 1.2.1 Product Quality Risks 1.2.2 Operational Risks 1.2.3 Regulatory Risks 1.2.4 Supply Chain Risks 1.2.5 Environmental and Safety Risks 1.2.6 Cybersecurity Risks 1.3.

“Navigating the Challenges of 3D Printing in Pharmaceutical Manufacturing”

1. Introduction 3D printing, also known as additive manufacturing, has emerged as a revolutionary technology in many industries, and the pharmaceutical sector is no exception. This technology, which creates objects layer by layer from digital models, holds the potential to reshape pharmaceutical manufacturing by enabling the development of personalized medicines, improving drug delivery systems, and

“Navigating the Challenges of 3D Printing in Pharmaceutical Manufacturing” Read More »

“Advancing Quality Control in Pharmaceutical Manufacturing: Techniques, Best Practices, and Future Trends”

1. Importance of Quality Control in Pharmaceuticals 1.1 Ensuring Patient Safety Quality control ensures that medications are free from contaminants, contain the correct ingredients, and meet the required potency levels to safeguard patient health. 1.2 Regulatory Compliance Pharmaceutical products must adhere to strict regulatory standards set by organizations such as the FDA, EMA, and WHO.

“Revolutionizing Pharmaceuticals: How AI is Transforming Manufacturing Processes”

1. The Role of AI in Pharmaceutical Manufacturing AI leverages advanced algorithms and machine learning techniques to analyze vast datasets, identify patterns, and provide actionable insights. In pharmaceutical manufacturing, this capability is being utilized across various stages of the production process, from research and development (R&D) to quality control and supply chain optimization. 2. Enhancing

“Revolutionizing Pharmaceuticals: How AI is Transforming Manufacturing Processes” Read More »

“Comprehensive Guide to Understanding Good Manufacturing Practices (GMP) in Pharma”

1. What Are Good Manufacturing Practices (GMP)? GMP refers to a set of regulations, codes, and guidelines that govern the manufacturing processes and environments in the pharmaceutical industry. These practices are enforced by regulatory bodies such as: GMP guidelines ensure that pharmaceutical products are consistently produced and controlled to meet predefined quality standards. 2. Importance

“Comprehensive Guide to Understanding Good Manufacturing Practices (GMP) in Pharma” Read More »

Standard Operating Procedure (SOP) for Batch Record Reconciliation

Batch Record Reconciliation is a critical process in pharmaceutical manufacturing that ensures all materials, components, and processes used in production are thoroughly documented, accounted for, and compliant with regulatory standards. This reconciliation involves verifying that every material issued, used, and returned is accurately recorded, thereby preventing discrepancies that could compromise product quality or traceability. Through detailed checks on quantities, production steps, and quality control data, batch record reconciliation provides a reliable, documented trail of the manufacturing process. This procedure not only supports quality assurance but also strengthens compliance with Good Manufacturing Practices (GMP) and regulatory requirements, essential for safeguarding product integrity and patient safety.

Standard Operating Procedure (SOP) for Batch Record Reconciliation Read More »

Standard Operating Procedure (SOP) on Data Integrity and ALCOA Principles in Batch Record Management

Data integrity is essential in batch record management to ensure that manufacturing records are accurate, reliable, and compliant with regulatory requirements. The foundation of data integrity is the ALCOA principles, which stand for Attributable, Legible, Contemporaneous, Original, and Accurate. These principles guide how data should be recorded and maintained to guarantee its quality and trustworthiness throughout its lifecycle.

Standard Operating Procedure for Deviation and Error Documentation

Deviation and Error Documentation is a critical component of quality management in industries like pharmaceuticals, manufacturing, and healthcare. This process involves systematically recording any deviation from established protocols or unplanned errors that occur during operations. The purpose is to ensure that each incident is thoroughly documented, investigated, and analyzed to identify root causes and implement corrective and preventive actions (CAPA). Effective deviation and error documentation promotes transparency, maintains regulatory compliance, and supports continuous improvement by preventing the recurrence of similar issues. It is an essential tool for risk mitigation and enhances overall operational efficiency and product quality, helping organizations meet quality standards and protect consumer safety.

Standard Operating Procedure for Deviation and Error Documentation Read More »

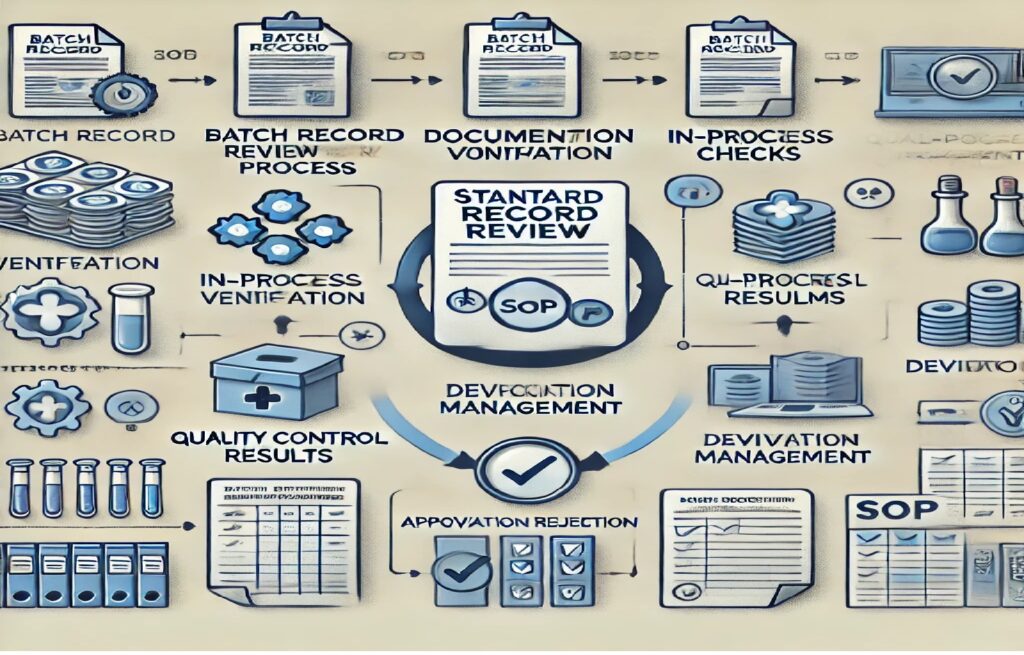

Standard Operating Procedure (SOP) for Batch Record Review

The purpose of this Standard Operating Procedure (SOP) is to establish a uniform process for reviewing and approving batch records in the pharmaceutical manufacturing process. This ensures that all products are consistently produced in compliance with Good Manufacturing Practices (GMP) and that the documentation accurately reflects the manufacturing process, quality control checks, and final product specifications.

Standard Operating Procedure (SOP) for Batch Record Review Read More »