Introduction to Pharmaceutical Contract Manufacturing

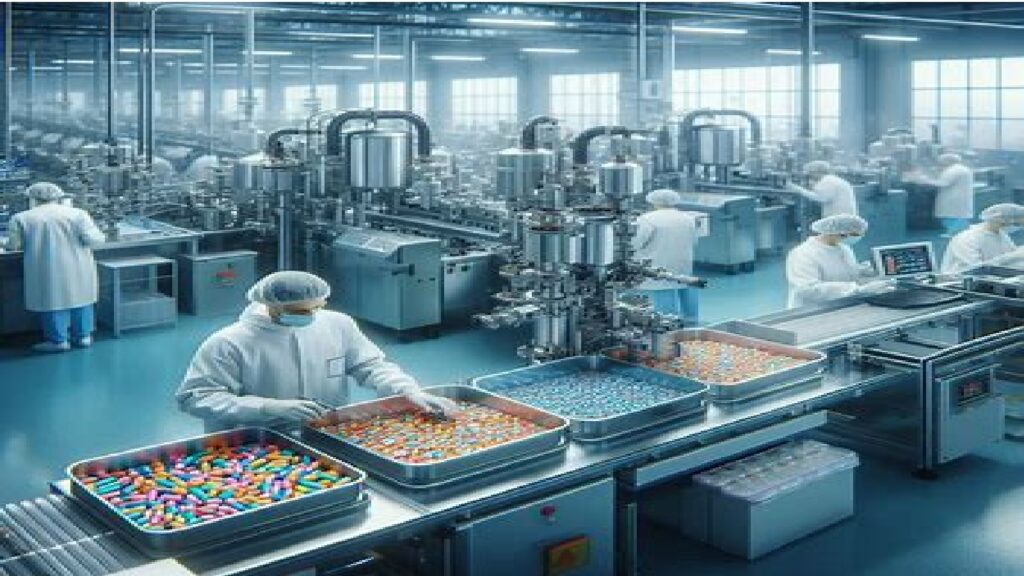

Pharmaceutical contract manufacturing refers to the outsourcing of drug production and related services to specialized third-party organizations. This model has gained significant traction globally, with the UK emerging as a pivotal hub due to its advanced healthcare infrastructure, skilled workforce, and adherence to stringent regulatory standards.

Why Choose Contract Manufacturing?

1. Cost Efficiency

Pharmaceutical production requires significant investment in infrastructure, equipment, and compliance measures. Contract manufacturing allows companies to:

- Avoid high capital expenditures.

- Save on operational costs such as maintenance, workforce salaries, and utilities.

- Access cost-effective manufacturing solutions without compromising on quality.

2. Expertise and Specialization

Contract manufacturers in the UK bring years of experience and specialized knowledge to the table. Their expertise enables:

- Compliance with stringent regulatory requirements like Good Manufacturing Practices (GMP).

- High-quality production across diverse therapeutic areas.

- Efficient handling of complex processes such as biologics production and sterile manufacturing.

3. Focus on Core Competencies

By outsourcing production, pharmaceutical companies can concentrate on:

- Research and development (R&D) for new drug formulations.

- Marketing and distribution strategies.

- Accelerating innovation without the distraction of manufacturing operations.

4. Access to Advanced Technology

UK-based CMOs leverage state-of-the-art facilities equipped with cutting-edge technology, offering:

- Advanced drug delivery systems.

- Robust formulation capabilities.

- High-precision manufacturing processes for APIs and finished products.

5. Scalability and Flexibility

Contract manufacturing provides the flexibility to scale operations as per demand. Companies can:

- Produce small batches for clinical trials or launch stages.

- Expand production to meet market demand during commercialization.

- Avoid risks associated with underutilized facilities during low demand periods.

6. Faster Time-to-Market

The pharmaceutical market is highly competitive, and time-to-market is critical. Contract manufacturers in the UK:

- Expedite production timelines through streamlined processes.

- Leverage their experience to navigate regulatory approvals efficiently.

- Enable companies to bring products to consumers faster, gaining a competitive edge.

The UK’s Advantage in Pharmaceutical Contract Manufacturing

1. World-Class Regulatory Environment

Adherence to Global Standards

The UK’s pharmaceutical industry operates under the stringent oversight of the Medicines and Healthcare products Regulatory Agency (MHRA). CMOs in the UK adhere to international standards, including:

- Good Manufacturing Practices (GMP).

- Good Distribution Practices (GDP).

- ISO certifications for quality and safety.

Streamlined Approvals

The MHRA provides clear guidelines and efficient approval processes, enabling companies to meet compliance requirements while maintaining production timelines.

2. Skilled and Experienced Workforce

High Levels of Expertise

The UK boasts a highly skilled workforce with expertise in pharmaceutical sciences, chemistry, and biotechnology. These professionals drive innovation and ensure precision in manufacturing.

Academic and Industry Collaboration

Strong ties between academia and the pharmaceutical industry foster research-driven manufacturing solutions, with universities like Oxford and Cambridge contributing to workforce development.

3. Advanced Manufacturing Infrastructure

Cutting-Edge Facilities

UK-based CMOs operate state-of-the-art facilities equipped with:

- High-capacity production lines for small- and large-scale manufacturing.

- Specialized equipment for sterile and biologics production.

- Advanced technologies like continuous manufacturing and single-use systems.

Emphasis on Innovation

Investment in emerging technologies, such as artificial intelligence (AI) and automation, enhances efficiency and precision in manufacturing processes.

4. Strong Focus on Quality Assurance

Rigorous Testing Protocols

UK CMOs prioritize quality assurance through comprehensive testing protocols, including:

- Analytical testing for APIs and formulations.

- Stability studies to ensure product longevity and efficacy.

- Real-time monitoring to maintain consistent quality during production.

Regulatory Audits

Frequent inspections and audits by regulatory bodies reinforce a commitment to safety and quality.

5. Strategic Geographic Location

Accessibility to Global Markets

The UK’s strategic location provides easy access to European, North American, and Asian markets. This geographic advantage streamlines:

- Supply chain logistics.

- Distribution of pharmaceutical products worldwide.

Well-Connected Transport Infrastructure

A robust network of ports, airports, and railways ensures seamless movement of raw materials and finished products.

6. Innovation in Biologics and Advanced Therapies

Expertise in Biologics Manufacturing

The UK is a leader in biologics, with CMOs specializing in:

- Monoclonal antibodies.

- Cell and gene therapies.

- Vaccines and biosimilars.

Support for Emerging Therapies

UK-based organizations are at the forefront of developing and manufacturing advanced therapies, capitalizing on the country’s thriving biotech ecosystem.

7. Sustainability and Environmental Responsibility

Green Manufacturing Practices

UK CMOs increasingly adopt eco-friendly practices, such as:

- Reducing carbon emissions through energy-efficient processes.

- Minimizing waste and implementing recycling initiatives.

Alignment with Global Goals

The UK’s commitment to sustainability aligns with global efforts to create a greener pharmaceutical industry.

Key Services Offered by Contract Manufacturers in the UK

1. Active Pharmaceutical Ingredient (API) Manufacturing

Expertise in API Synthesis

UK CMOs specialize in the production of high-quality APIs, which form the foundation of pharmaceutical products. Their capabilities include:

- Complex chemical synthesis.

- Biotechnological production methods for biologics.

- Compliance with stringent regulations like Good Manufacturing Practices (GMP).

Custom API Development

Contract manufacturers also offer tailored API solutions to meet the unique needs of pharmaceutical companies, ensuring efficacy, safety, and scalability.

2. Formulation Development

Optimizing Drug Formulations

UK CMOs are adept at developing drug formulations that enhance bioavailability, stability, and patient compliance. Their expertise includes:

- Oral solid dosages such as tablets and capsules.

- Parenteral forms, including injectables.

- Topical formulations like creams and gels.

Advanced Drug Delivery Systems

Innovations in drug delivery, such as sustained-release and targeted delivery systems, are a hallmark of UK contract manufacturing services.

3. Clinical Trial Manufacturing

Small-Scale Production for Trials

Contract manufacturers in the UK cater to the specific needs of clinical trials by offering:

- Small-batch production.

- Blinding and randomization of trial samples.

- Packaging and labeling tailored for clinical studies.

Regulatory Compliance for Trials

UK CMOs ensure that trial materials meet the regulatory requirements of both domestic and international markets, facilitating smooth approvals and testing.

4. Packaging and Labeling

Compliant Packaging Solutions

Packaging is a critical component of the pharmaceutical supply chain, and UK CMOs provide:

- Primary and secondary packaging.

- Child-resistant and tamper-evident designs.

- Customized packaging for specific markets.

Labeling for Global Markets

CMOs offer multilingual labeling services that comply with the regulatory standards of various regions, ensuring accurate and transparent information.

5. Analytical and Stability Testing

Comprehensive Testing Services

To ensure product safety and efficacy, UK CMOs provide a range of analytical testing services, including:

- Raw material testing.

- Finished product quality analysis.

- Microbiological testing.

Stability Studies

Stability testing ensures that pharmaceutical products maintain their potency, safety, and efficacy over their shelf life. CMOs conduct:

- Accelerated stability studies.

- Long-term stability studies under various environmental conditions.

6. Regulatory Support and Documentation

Navigating Complex Regulations

Contract manufacturers in the UK assist pharmaceutical companies in meeting complex regulatory requirements by providing:

- Dossier preparation for drug approvals.

- GMP audits and certifications.

- Expert guidance on compliance with agencies like the MHRA, EMA, and FDA.

Supporting Market Approvals

UK CMOs prepare and submit comprehensive documentation to regulatory bodies, expediting the approval process for new drugs and formulations.

7. Biologics and Biosimilars Manufacturing

Advanced Biologics Production

The UK has a strong foothold in biologics manufacturing, with CMOs specializing in:

- Monoclonal antibodies.

- Recombinant proteins.

- Vaccines and cell-based therapies.

Focus on Biosimilars

The increasing demand for cost-effective biologics has driven UK CMOs to develop biosimilar products that meet global quality standards.

8. Supply Chain Management

Integrated Supply Solutions

UK CMOs provide end-to-end supply chain management services, ensuring timely procurement of raw materials and efficient distribution of finished products.

Risk Mitigation Strategies

By employing robust supply chain strategies, contract manufacturers minimize risks associated with delays, shortages, and disruptions.

Leading Contract Manufacturing Organizations (CMOs) in the UK

1. Catalent Pharma Solutions

Overview

Catalent is a global leader with a strong presence in the UK, specializing in drug development and delivery solutions.

Key Services

- Oral, injectable, and inhalable drug manufacturing.

- Biologics production, including monoclonal antibodies.

- Clinical trial supply services.

Unique Strengths

Catalent’s advanced delivery technologies and large-scale manufacturing capabilities make it a preferred partner for complex pharmaceutical projects.

2. Recipharm

Overview

Recipharm is a global pharmaceutical CDMO with multiple facilities in the UK, offering end-to-end manufacturing solutions.

Key Services

- API development and production.

- Formulation development for oral, inhalation, and parenteral drugs.

- Regulatory support and dossier preparation.

Unique Strengths

Recipharm’s expertise in small-molecule manufacturing and strong regulatory support are its defining attributes.

3. Aesica Pharmaceuticals

Overview

Part of the Consort Medical Group, Aesica specializes in pharmaceutical and medical device manufacturing, focusing on innovation and quality.

Key Services

- API manufacturing and formulation.

- Drug delivery systems and device integration.

- Specialized services for controlled substances.

Unique Strengths

Aesica’s integration of drug-device combinations provides unique value to clients seeking holistic solutions.

4. PCI Pharma Services

Overview

PCI Pharma Services is a leading provider of clinical and commercial packaging solutions with extensive manufacturing capabilities.

Key Services

- Packaging and labeling for clinical trials.

- Specialized manufacturing for high-potency drugs.

- Serialization and anti-counterfeiting measures.

Unique Strengths

PCI’s focus on secure, compliant packaging and cutting-edge labeling technologies ensures quality and traceability.

5. Almac Group

Overview

Almac is a UK-based CMO renowned for its comprehensive range of pharmaceutical services, from research to commercialization.

Key Services

- Custom API synthesis.

- Solid dose and sterile product manufacturing.

- Analytical and stability testing.

Unique Strengths

Almac’s integrated solutions and global reach make it a versatile partner for pharmaceutical companies of all sizes.

6. Fareva

Overview

Fareva provides pharmaceutical, cosmetics, and industrial manufacturing solutions with operations in the UK.

Key Services

- Oral and topical drug manufacturing.

- Sterile product development and production.

- Biologics and high-potency drug handling.

Unique Strengths

Fareva’s expertise in diverse formulations and commitment to sustainability set it apart in the contract manufacturing landscape.

7. Sharp Clinical Services

Overview

Sharp specializes in clinical trial packaging, labeling, and supply chain services, with facilities in the UK.

Key Services

- Packaging and distribution for clinical trials.

- Blinding and randomization.

- Storage and logistics solutions.

Unique Strengths

Sharp’s focus on clinical trial needs ensures precision and compliance, making it a reliable partner for early-stage drug development.

8. Thermo Fisher Scientific (Patheon)

Overview

Thermo Fisher Scientific, through its Patheon brand, provides extensive pharmaceutical manufacturing and development services.

Key Services

- API and biologics production.

- Finished dosage form manufacturing.

- Clinical and commercial manufacturing.

Unique Strengths

Patheon’s combination of advanced facilities and global expertise ensures seamless production and delivery of pharmaceutical products.

Challenges in the UK Pharmaceutical Contract Manufacturing Landscape

1. Regulatory Complexity

Stringent Compliance Requirements

UK CMOs must comply with stringent regulations from bodies such as the Medicines and Healthcare products Regulatory Agency (MHRA), European Medicines Agency (EMA), and US Food and Drug Administration (FDA). The overlapping and evolving nature of these requirements can:

- Slow down production timelines.

- Increase operational costs due to frequent audits and documentation updates.

Post-Brexit Regulatory Uncertainty

The UK’s departure from the EU has added layers of complexity:

- Divergence in UK and EU regulations creates additional compliance burdens.

- Pharmaceutical companies must navigate dual approval processes to access both markets.

2. Rising Manufacturing Costs

High Operational Expenses

Manufacturing in the UK is associated with elevated costs due to:

- Expensive raw materials.

- High energy and utility prices.

- Labour costs driven by a skilled but competitive workforce.

Price Pressures from Global Markets

UK CMOs face price competition from countries like India and China, where production costs are significantly lower, making it challenging to maintain profitability.

3. Supply Chain Disruptions

Raw Material Dependency

The UK relies heavily on imported raw materials, especially Active Pharmaceutical Ingredients (APIs), from global suppliers. Factors such as:

- Delays in international shipping.

- Volatility in raw material prices.

- Geopolitical tensions impacting trade routes.

Post-Pandemic Supply Chain Strains

The COVID-19 pandemic highlighted vulnerabilities in the supply chain, leading to shortages and delayed timelines for contract manufacturers.

4. Technological Advancements and Integration

High Investment Costs

Adopting cutting-edge technologies like automation, AI, and advanced bioprocessing requires significant capital investment, which:

- Increases financial strain on smaller CMOs.

- Creates a competitive gap between large, well-funded organizations and smaller players.

Skilled Workforce Shortage

While the UK has a skilled workforce, there is a shortage of experts in emerging fields like biologics manufacturing and digital transformation, hindering technology adoption.

5. Environmental and Sustainability Concerns

Regulatory Push for Sustainability

Stricter environmental regulations require CMOs to adopt sustainable practices, such as:

- Reducing carbon emissions.

- Managing pharmaceutical waste effectively.

- Utilizing renewable energy sources.

Financial Burden of Green Practices

Implementing eco-friendly solutions often involves significant upfront costs, impacting the bottom line of many CMOs.

6. Market Competition and Consolidation

Competition from Emerging Markets

UK CMOs face growing competition from low-cost manufacturing hubs in Asia and Eastern Europe, where labor and production expenses are lower.

Industry Consolidation

The trend of mergers and acquisitions in the pharmaceutical sector has:

- Reduced the number of clients for mid-sized CMOs.

- Shifted preference towards larger, integrated CMOs that offer end-to-end services.

7. Capacity Constraints and Scalability

Limited Manufacturing Capacities

Some UK CMOs struggle with limited capacity to handle large-scale production, particularly for biologics and personalized medicines.

Scalability Challenges

Scaling operations to meet global demand often requires infrastructure upgrades, which are expensive and time-intensive.

Strategies to Overcome Challenges

1. Embracing Technological Innovations

Investing in automation, AI, and advanced analytics can streamline operations, reduce costs, and improve quality.

2. Strengthening Supply Chains

UK CMOs should explore local sourcing options and diversify suppliers to mitigate risks of global supply chain disruptions.

3. Collaborative Efforts

Partnerships between CMOs, pharmaceutical companies, and government bodies can:

- Share financial burdens of technology adoption.

- Foster innovation through shared resources and expertise.

4. Sustainability Initiatives

Adopting green manufacturing processes and investing in renewable energy can align with global trends while meeting regulatory requirements.

5. Regulatory Harmonization

Efforts to align UK regulations with international standards can reduce compliance burdens and attract more clients.

Future Outlook for Pharmaceutical Contract Manufacturing in the UK

Emerging Trends in Pharmaceutical Contract Manufacturing

1. Growth in Biologics Manufacturing

The demand for biologics, including vaccines, monoclonal antibodies, and cell and gene therapies, is rising globally. UK CMOs are increasingly investing in facilities and expertise to handle complex biologics manufacturing.

- Market Expansion: Biologics are expected to account for a significant share of pharmaceutical production in the coming years.

- Specialized Expertise: CMOs focusing on biologics will be key players, leveraging their advanced technologies and processes.

2. Personalized Medicine

The rise of personalized medicine, driven by advancements in genomics and precision medicine, requires small-batch, high-quality manufacturing.

- Tailored Solutions: CMOs will need to adapt to produce patient-specific therapies.

- Rapid Turnaround: Quick production cycles will be essential for personalized treatments.

3. Technological Advancements

Technological innovations are reshaping pharmaceutical manufacturing:

- Automation and AI: Enhanced efficiency and reduced costs through automated processes and AI-driven analytics.

- Continuous Manufacturing: Transitioning from batch to continuous manufacturing for greater consistency and scalability.

4. Sustainability Initiatives

Sustainability is becoming a central focus for pharmaceutical companies and CMOs alike.

- Green Practices: Energy-efficient processes and waste reduction will become standard.

- Compliance: Regulatory pressure to adopt environmentally friendly practices will drive investment in sustainable manufacturing.

Opportunities for UK CMOs

1. Post-Brexit Trade Opportunities

Brexit has created both challenges and opportunities:

- Global Partnerships: UK CMOs can strengthen ties with non-EU countries, expanding their client base.

- Focus on Innovation: The need to remain competitive will push CMOs to innovate and improve services.

2. Expansion into Emerging Markets

Emerging markets in Asia, Africa, and South America present new opportunities for UK CMOs.

- Affordable Solutions: By offering cost-effective manufacturing, UK CMOs can tap into these growing markets.

- Regulatory Expertise: UK CMOs’ strong compliance capabilities make them attractive partners for companies entering regulated markets.

3. Advanced Therapies and Rare Diseases

The focus on advanced therapies and rare disease treatments opens niche opportunities.

- High-Value Manufacturing: Producing high-margin drugs for rare conditions.

- Partnerships: Collaborations with biotech companies developing novel therapies.

Conclusion

Pharmaceutical contract manufacturing in the UK stands as a cornerstone of the global pharmaceutical supply chain, offering unmatched quality, reliability, and innovation. With its strong regulatory framework, skilled workforce, and advanced infrastructure, the UK is well-positioned to remain a leader in this critical sector. Companies seeking to optimize production and navigate the complexities of drug development will find the UK’s contract manufacturing landscape a robust partner in achieving their goals.

For more articles, Kindly Click here.

For pharmaceutical jobs, follow us on LinkedIn

For Editable SOPs in Word format contact us on info@pharmaceuticalcarrier.com

For more information kindly follow us on www.pharmaguidelines.co.uk