1. Purpose

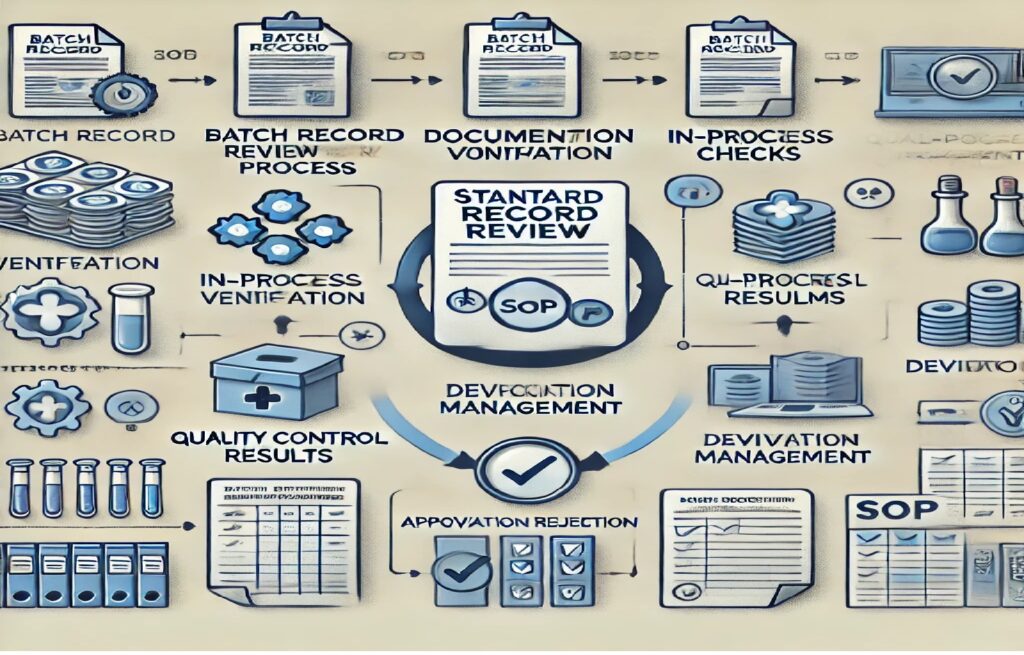

The purpose of this Standard Operating Procedure (SOP) is to outline the systematic procedure for reviewing batch production records. Batch record review is essential to ensure that all production steps comply with Good Manufacturing Practices (GMP) and regulatory requirements, ultimately ensuring product quality and consistency.

2. Scope

This SOP applies to the Quality Assurance (QA) department responsible for reviewing batch production records for all manufactured products within the facility. It covers initial review, intermediate review, and final release.

3. Responsibilities

3.1. Responsibilities of Quality Assurance (QA) in Batch Record Review

1. Receiving and Organizing Batch Records

- Collecting Batch Documentation: QA is responsible for receiving completed batch records from the production department once a batch is completed. This includes all associated documents, such as production logs, in-process control records, and QC test results.

- Document Verification: QA must verify that all required documents are attached and organized before beginning the review. This includes checking the presence of manufacturing records, equipment usage logs, and laboratory testing data.

2. Ensuring Completeness and Accuracy

- Reviewing Data Entry Accuracy: QA checks that all entries are complete, legible, and accurately filled out by the production team. This includes confirming correct batch numbers, manufacturing dates, expiry dates, and signatures.

- Completeness of Information: QA ensures that all sections of the batch record are filled, with no fields left blank or unaddressed. QA must also check that critical steps in the batch record are signed and dated by responsible personnel.

- Verifying Compliance with SOPs: Each step in the record must align with the facility’s Standard Operating Procedures (SOPs) to ensure adherence to approved methods and processes.

3. Review of Raw Materials and Inventory Management

- Cross-Checking Raw Material Usage: QA verifies that the materials used match the approved bill of materials and that correct lot numbers and quantities are recorded.

- Material Dispensing and Verification: QA confirms that materials were dispensed, documented, and used according to the pre-defined process.

- Inventory Reconciliation: QA ensures that records of material usage and remaining inventory match facility inventory management systems, helping to identify discrepancies early.

4. Verifying Process Parameters and Equipment Usage

- Ensuring Process Consistency: QA checks the documented process parameters (e.g., temperature, pressure, mixing time) to confirm they are within approved limits and match specifications.

- Equipment Verification: QA verifies that the equipment listed in the record was used for the batch and checks maintenance and calibration records for compliance. Any equipment-related deviations must be documented and investigated.

5. Intermediate and In-Process Control Checks

- Reviewing In-Process Control Data: QA reviews in-process control checks, including sampling, testing, and inspection results at each critical stage to ensure they fall within acceptable limits.

- Recording of Process Deviations: Any deviations from the standard process must be documented, reviewed, and approved. QA is responsible for confirming that deviations were correctly documented and that corrective and preventive actions (CAPA) were implemented.

6. Reviewing Quality Control (QC) Results

- Assessing QC Test Results: QA verifies the QC test data, including physical, chemical, and microbiological results, to ensure they meet product specifications.

- Batch Disposition Based on QC Results: If the batch meets all quality standards, QA proceeds to approve it for release; if not, they initiate corrective actions or rejection procedures.

- Stability and Validation Checks: For certain batches, stability and validation results may be required to confirm product quality. QA ensures these additional requirements are met before approving a batch.

7. Documentation Compliance and Record Corrections

- Corrective Documentation Practices: QA checks that all documentation complies with Good Documentation Practices (GDP). This includes legible writing, correct dating, and proper error correction procedures.

- Ensuring Traceability: QA ensures that all records are traceable, with initials or signatures and timestamps where applicable, to identify personnel involved in each production step.

- Correcting and Clarifying Entries: Any illegible or ambiguous entries should be clarified, and QA should coordinate with the production team for clarifications and make corrections according to SOPs.

8. Investigation of Deviations and Discrepancies

- Deviation Investigation: QA investigates any deviations noted during batch processing, determining their impact on product quality. This includes root cause analysis and evaluation of the deviation on batch integrity.

- Implementing CAPA: QA develops corrective and preventive actions for identified deviations and ensures their effective implementation. These actions are documented within the batch record.

- Follow-Up on Discrepancies: QA verifies that all discrepancies are documented, resolved, and appropriately justified in the record before final approval.

9. Final Batch Record Review and Approval

- Final Verification: QA performs a final review of the batch record, ensuring it meets all facility and regulatory requirements. Any outstanding issues must be resolved prior to batch approval.

- Batch Release or Rejection: Based on the review, QA either approves the batch for release or rejects it if quality standards are not met. This step is documented with signatures and dates of QA personnel.

- Document Archiving: QA ensures the final batch record is archived in the designated storage area, making it retrievable for inspections and audits.

10. Supporting Audits and Compliance Inspections

- Providing Documentation for Audits: QA assists with regulatory and internal audits by providing batch records and explaining documentation practices.

- Ensuring Ongoing Compliance: QA’s review process aims to identify patterns in deviations or documentation errors, enabling continuous improvement in SOPs and training.

3.2. Responsibilities of Production Department in Batch Record Review

The Production Department is responsible for accurately documenting all aspects of the manufacturing process in the batch records, ensuring that the batch is produced in compliance with Good Manufacturing Practices (GMP), regulatory standards, and internal Standard Operating Procedures (SOPs). The following are the detailed responsibilities of the Production Department in the batch record review process:

1. Accurate and Complete Documentation

- Recording Manufacturing Details: The Production Department is responsible for accurately recording all details of the manufacturing process, including batch number, manufacturing date, expiry date, and all operational steps. This documentation provides a traceable history of the production process.

- Completeness of Batch Records: Each section of the batch record should be filled completely, with no missing information. This includes signatures, dates, and initials of personnel involved in each stage of the process.

2. Raw Material Verification and Documentation

- Material Dispensing Records: Production personnel must record the dispensing and use of raw materials, including lot numbers, quantities, and usage dates, to ensure traceability.

- Checking Material Specifications: All materials should be checked to confirm that they meet the approved specifications for the batch. If a deviation is found, it should be documented and reported to Quality Assurance (QA) for further investigation.

3. Process Parameter Documentation

- Documenting Process Parameters: All critical process parameters (e.g., temperature, mixing time, speed) must be recorded in the batch record, verifying that they are within specified ranges approved in the SOPs.

- Equipment Operation Details: Production is responsible for documenting equipment used, batch size, process duration, and specific settings, ensuring all equipment is identified by name and ID and calibrated and maintained per schedule.

4. Conducting and Recording In-Process Checks

- In-Process Control Documentation: Production personnel must perform and document in-process checks at specified stages (e.g., weight checks, pH levels, mixing times). These controls ensure that the batch is progressing according to specifications.

- Immediate Reporting of Deviations: Any deviation from the standard process should be recorded immediately, with an explanation provided in the batch record. Production personnel should notify QA and follow SOPs to resolve the deviation.

5. Batch Yield Calculation and Verification

- Recording Yield Data: Production personnel are responsible for accurately recording actual yields at various production stages and calculating final yields. This includes recording both theoretical and actual yields.

- Ensuring Yield Consistency: The Production Department must verify that yields are within acceptable limits defined in the SOPs. If the yield is outside the allowable range, it should be documented and investigated.

6. Equipment and Facility Maintenance Documentation

- Equipment Usage Logs: Production is responsible for documenting the use of equipment, confirming that it is in good working order, calibrated, and has undergone any necessary maintenance before use.

- Cleanliness and Safety Checks: Production personnel must ensure that equipment is cleaned, sanitized, and suitable for use, following documented cleaning procedures and completing cleaning logs. This minimizes contamination risk and ensures adherence to GMP standards.

7. Deviation Management

- Documenting Deviations: Any deviation from standard procedures must be recorded in detail within the batch record. This includes the nature of the deviation, corrective actions taken, and personnel involved.

- Supporting QA in Deviation Investigations: Production personnel should work collaboratively with QA during deviation investigations to identify root causes and implement corrective and preventive actions (CAPA).

- Preventive Actions for Recurring Issues: If deviations occur frequently, Production should assess the process to identify potential improvements, helping prevent recurrence.

8. Ensuring Compliance with Good Documentation Practices (GDP)

- Following Documentation Protocols: Production personnel must ensure that all entries are legible, complete, and follow GDP guidelines, including using indelible ink, avoiding erasures, and using approved correction methods.

- Correcting Errors Properly: If corrections are necessary, personnel should cross out errors with a single line, initial, and date each correction, providing an explanation if needed.

- Maintaining Documentation Consistency: Consistent formatting, terminology, and units should be used throughout the batch record for clarity and accuracy.

9. Reviewing and Signing Off Batch Record Entries

- Initial Review of Entries: Production supervisors are responsible for performing an initial review of completed entries to ensure accuracy before submitting the batch record to QA.

- Signature Verification: Production personnel must sign, date, and initial entries as required, ensuring accountability for each stage of production.

- Final Production Review: Before submitting the batch record to QA, the Production Department must conduct a final review, checking for completeness, accuracy, and compliance with SOPs.

10. Supporting Quality Assurance (QA) in Batch Record Review

- Providing Clarifications: Production personnel must be available to answer questions or provide clarifications about recorded data during the QA review process.

- Supporting Investigations: If any discrepancies, errors, or deviations are identified by QA, the Production Department should collaborate with QA to investigate and address issues.

- Implementing QA Recommendations: Based on QA’s review, Production may be required to implement corrective actions, amend documentation, or make process improvements to prevent recurrence.

11. Archiving and Storage of Completed Records

- Organized Storage: The Production Department is responsible for organizing and safely storing all batch records until they are transferred to QA for final review. Records should be accessible for audit or inspection.

- Ensuring Record Integrity: Ensure that all batch records are preserved without damage, alteration, or loss, supporting data integrity and traceability requirements.

3.3.Responsibilities of Quality Control (QC) in Batch Record Review

The Quality Control (QC) department plays an essential role in the batch record review process to verify the quality, purity, and compliance of each batch produced. QC ensures that testing, documentation, and results meet required standards and that any deviations or abnormalities are promptly addressed. The following are the detailed responsibilities of the QC department in the batch record review process:

1. Review of Analytical Data and Test Results

- Verifying Analytical Data: QC is responsible for reviewing all analytical data generated during batch testing. This includes verifying accuracy, completeness, and adherence to specifications for critical quality attributes (e.g., potency, purity).

- Ensuring Consistency with Specifications: QC checks that test results align with the specifications established for the product. Any result outside specified limits should be flagged and investigated as an out-of-specification (OOS) result.

2. Documentation of Testing Procedures

- Recording Testing Parameters and Results: QC ensures that all testing parameters, such as instrument settings and environmental conditions, are accurately recorded in the batch record.

- Ensuring Traceability: Each test result must be traceable to the analyst who performed it, the date and time of testing, and the equipment used. This ensures accountability and traceability in case further investigation is required.

3. Equipment Calibration and Maintenance Verification

- Ensuring Equipment Readiness: QC verifies that all analytical instruments and equipment used in testing are calibrated and maintained according to established schedules before use.

- Documenting Calibration Status: QC includes calibration logs or records of equipment used in testing, confirming that each instrument’s calibration status is current and meets validation requirements.

- Preventing Equipment Deviations: QC should monitor equipment performance during testing and document any instances where deviations are noted, reporting them for further evaluation.

4. Sample Management and Tracking

- Sample Identification and Labeling: QC is responsible for accurate sample identification and labeling throughout the testing process to prevent mix-ups and ensure sample traceability.

- Documenting Sample Collection and Testing Dates: Each sample collected for testing must be documented with collection and testing dates to ensure that testing timelines and conditions are within allowed limits.

- Adhering to Retention Requirements: QC ensures proper retention and storage of samples as per regulatory guidelines and SOPs for any future reference or re-testing needs.

5. Out-of-Specification (OOS) and Out-of-Trend (OOT) Management

- Investigating OOS Results: QC is responsible for promptly investigating any OOS results. This includes conducting a root cause analysis and documenting the findings in the batch record.

- Handling OOT Results: If any result trends outside of normal ranges, QC should assess potential root causes and document these findings. OOT investigations are critical to identifying any issues early in the production process.

- Documenting Corrective Actions: QC should record corrective and preventive actions (CAPA) for any OOS or OOT findings, collaborating with QA to ensure these are implemented and monitored for effectiveness.

6. Verification of Raw Material and Component Quality

- Testing of Raw Materials: QC is responsible for testing and verifying that all raw materials meet quality specifications before use in batch production. This ensures that only approved materials are used.

- Verifying Packaging and Labeling Materials: QC tests and inspects packaging materials to ensure they meet quality and regulatory requirements, preventing contamination or degradation of the product.

- Ensuring Documentation Completeness: QC must document test results for all raw materials and components, including lot numbers and acceptance criteria.

7. Environmental Monitoring and Microbiological Testing

- Monitoring Environmental Conditions: QC documents environmental monitoring, including cleanliness, temperature, and humidity, in the batch record. These factors impact product quality and must be maintained within limits.

- Microbiological Testing and Documentation: For sterile or microbiologically sensitive products, QC is responsible for documenting microbiological test results. Any contamination findings should be investigated and recorded, and corrective actions must be taken.

8. Quality Attribute Testing and Product Conformance

- Reviewing Finished Product Testing: QC verifies that final product testing aligns with established specifications for critical attributes such as potency, disintegration, dissolution, and stability.

- Product Conformance Documentation: QC ensures all critical quality attributes are tested and documented. Any deviations should be addressed, with corrective actions documented in the batch record.

- Batch Conformance Reporting: QC provides a final report on product conformance, which is then added to the batch record, forming the basis for QA’s decision on batch release.

9. Adherence to Good Documentation Practices (GDP)

- Ensuring Legibility and Accuracy: QC personnel must adhere to Good Documentation Practices (GDP), ensuring all entries are legible, accurate, and free from errors.

- Proper Correction Procedures: Any corrections to QC documentation must follow GDP guidelines, with single-line cross-outs, initials, and dates. This ensures transparency and maintains the integrity of the data.

- Verification of Test Results: QC reviews all entries for accuracy, ensuring they meet GDP standards before signing off on the documentation.

10. Supporting Quality Assurance (QA) in Batch Record Review

- Providing Clarifications and Support: QC provides additional clarification to QA during the batch record review process if required, particularly for OOS, OOT, or other atypical results.

- Documenting and Explaining Deviations: Any deviations or anomalies noted in testing should be well-documented by QC, with root cause analysis findings provided to QA for comprehensive review.

- Coordinating with QA for CAPA: QC collaborates with QA to ensure CAPA actions are effectively implemented, documented, and monitored to prevent recurrence of issues.

11. Batch Release Decision Support

- Completing Final Review of Test Results: QC ensures all testing for the batch is complete, and results meet established specifications before supporting QA’s batch release decision.

- Providing Test Summary: QC provides a summary report of all testing and documentation findings for the batch record to aid QA in final approval.

- Assisting with Release or Rejection Decisions: QC provides input to QA for final disposition of the batch based on quality testing, OOS findings, or unresolved deviations that may impact product safety or efficacy.

12. Preparation for Audits and Regulatory Inspections

- Ensuring Documentation Readiness: QC is responsible for maintaining complete and compliant batch documentation, ready for regulatory audits and inspections.

- Assisting with Regulatory Queries: During audits, QC supports QA by providing clarification on testing procedures, analytical data, and documentation practices.

- Implementing Audit Findings: If any issues are noted during an audit, QC coordinates with QA to implement corrective actions and updates batch record documentation to reflect any changes.

3.4.Responsibilities of Warehouse and Logistics in Batch Record Review

The Warehouse and Logistics department plays an essential role in the batch record review process by ensuring the proper management, handling, and traceability of raw materials, packaging components, and finished goods. Their responsibilities directly impact product quality, compliance, and the overall integrity of the batch. Here is a detailed breakdown of the Warehouse and Logistics department’s responsibilities in batch record review:

1. Material Receiving and Inspection

- Verification of Received Materials: Warehouse personnel are responsible for verifying the quality and quantity of all incoming raw materials, packaging materials, and components. This includes checking the condition, batch number, and lot information against purchase orders.

- Documentation of Material Receipt: All details of received materials, including supplier information, date of receipt, and inspection outcomes, must be accurately documented. This information is crucial for traceability in the batch record.

- Labeling and Identification: Upon receipt, materials must be labeled with unique identification numbers, batch numbers, and storage requirements. Proper labeling ensures traceability throughout production and batch review.

2. Proper Storage and Handling of Materials

- Maintaining Storage Conditions: Warehouse staff ensures that raw materials and components are stored under specified conditions (e.g., temperature, humidity) to preserve quality. Storage conditions are documented and monitored regularly to prevent contamination or degradation.

- Segregation of Materials: Proper segregation of approved, quarantined, and rejected materials helps prevent mix-ups and cross-contamination. Warehouse personnel should maintain clear documentation to differentiate these categories.

- FIFO and FEFO Compliance: Warehouse follows First-In-First-Out (FIFO) or First-Expiry-First-Out (FEFO) procedures for material distribution, which ensures older or soon-to-expire materials are used first, reducing waste and maintaining compliance.

3. Issuance and Dispensing of Materials

- Material Request Fulfillment: The Warehouse team is responsible for issuing and dispensing materials to production based on manufacturing requirements. Each issuance should be verified against the production plan to avoid excess or shortage.

- Documentation of Issuance: The quantity, batch number, and lot number of materials issued must be documented in the batch record. Any discrepancies should be immediately reported and resolved.

- Ensuring Material Traceability: Warehouse staff ensures that every material dispensed can be traced back to its supplier, receipt date, and storage conditions, which is essential for the traceability in batch records.

4. Material Reconciliation and Returns Management

- Reconciliation of Used Materials: After production, Warehouse personnel are responsible for reconciling the amount of material issued with the amount consumed and returned. Any significant discrepancies must be investigated and documented.

- Handling Returned Materials: Materials returned to the warehouse from production, including unused or rejected materials, should be properly documented. Returned materials may require re-evaluation before re-storage or disposal.

- Documenting Disposal of Expired or Damaged Materials: Expired, damaged, or rejected materials should be recorded and disposed of according to company SOPs and regulatory guidelines. Proper documentation ensures compliance and supports the batch record review process.

5. Control of Packaging Materials

- Receipt and Inspection of Packaging Materials: Warehouse staff inspects packaging materials upon receipt to ensure they meet specified quality and regulatory standards. Only approved packaging materials should be used in production.

- Traceability of Packaging Components: Warehouse personnel must maintain complete records of packaging materials, including batch numbers and supplier information. This traceability is essential for accurate batch record review.

- Issuance and Reconciliation of Packaging Materials: Warehouse documents the quantity of packaging materials issued for each batch and reconciles them post-production. Any discrepancies must be investigated and recorded.

6. Management of Finished Goods

- Storage of Finished Goods: Warehouse ensures that finished goods are stored under appropriate conditions (e.g., temperature, humidity) as specified in product requirements, maintaining product quality until distribution.

- Labeling and Traceability of Finished Products: Finished products are labeled with unique identifiers for tracking throughout storage and distribution. This traceability is important for product recall, if necessary, and supports batch record review.

- Preparation for Shipment: The logistics team is responsible for preparing finished goods for shipment, ensuring that packaging and labeling meet regulatory and client requirements for safe and compliant distribution.

7. Batch Traceability and Record Maintenance

- Ensuring Complete Documentation: Warehouse personnel document every stage of material handling, from receipt to issuance, storage, and dispatch. These records are an integral part of the batch record, ensuring traceability and compliance.

- Archiving and Record Retention: Warehouse is responsible for retaining records for a defined period according to SOPs and regulatory requirements, enabling access to batch records in case of an audit or recall.

- Cross-Referencing with Production Records: Warehouse records should align with production records, allowing Quality Assurance (QA) to verify traceability and ensure batch record completeness.

8. Collaboration with Quality Assurance (QA)

- Providing Documentation for Batch Review: The Warehouse team provides complete documentation of material handling activities to QA for batch record review. This includes records of material issuance, returns, and any material-related deviations.

- Assisting in Deviation Investigations: In cases where there are material-related discrepancies, such as shortages, excess issuance, or incorrect storage conditions, Warehouse assists QA in investigating and documenting root causes.

- Supporting CAPA Implementation: If deviations or material issues require corrective actions, Warehouse coordinates with QA to implement and document corrective actions, ensuring that material handling practices align with compliance requirements.

9. Management of Inventory Control Systems

- Maintaining Accurate Inventory Records: Warehouse staff ensures that all inventory records in the system are accurate and updated in real time, allowing for precise material tracking and reconciliation.

- Using ERP or LIMS Systems: For facilities using automated systems (e.g., ERP, LIMS), Warehouse staff is responsible for maintaining accurate data entry, facilitating batch tracking and material allocation during batch record review.

- Monitoring Stock Levels and Expiry Dates: Warehouse monitors inventory levels and the expiry dates of materials, ensuring materials are used before expiration and reporting any issues to QA for action.

10. Compliance with Good Warehousing Practices (GWP)

- Adherence to Standard Operating Procedures (SOPs): Warehouse staff must strictly follow SOPs for all material handling processes to ensure consistent and compliant practices across batches.

- Training and Continuous Improvement: Warehouse staff should be trained on GWP and any updates to material handling or documentation processes to maintain quality and regulatory compliance.

- Regular Audits and Self-Inspections: The Warehouse department performs regular self-inspections to identify and correct any deviations in material handling or storage practices. Findings are documented and reviewed to ensure continuous improvement.

11. Support in Product Recall and Audit Readiness

- Recall Readiness and Batch Traceability: Warehouse ensures that materials and finished products can be traced back through each batch record, supporting rapid response in the event of a product recall.

- Providing Documentation for Audits: During audits, Warehouse supports QA by providing complete, accurate records for material handling, storage, and distribution, demonstrating adherence to regulatory standards.

- Implementing Audit Findings: If audit findings identify areas for improvement, Warehouse collaborates with QA to implement corrective actions and update documentation practices accordingly.

4. Definitions

- Batch Record (BR): A set of documents that provide a detailed record of all aspects of production for a specific batch, including raw material usage, processing parameters, quality checks, and packaging details.

- Good Manufacturing Practice (GMP): A system for ensuring that products are consistently produced and controlled according to quality standards.

5. Procedure

5.1 Initial Review of Batch Record

- Receiving Batch Records:

- QA should receive completed batch records from the Production Department once the production process is complete.

- Check that all required documents (e.g., batch records, QC testing results, packaging records) are included.

- Preliminary Verification:

- Verify that all batch records are legible and completed.

- Ensure that each section is signed and dated by the responsible personnel.

- If any sections are incomplete or unclear, return the record to the production team for clarification.

- Review of Critical Sections:

- Examine all critical areas, such as:

- Raw Material Usage: Confirm that materials used align with the bill of materials and are logged with correct lot numbers.

- Process Parameters: Verify that processing steps followed approved specifications and were performed within the acceptable range.

- Equipment Usage: Ensure that equipment is identified, and check for preventive maintenance and calibration status.

- Yield Calculation: Confirm that actual yield matches expected yield within allowable limits.

- Cross-check batch number, manufacturing date, and expiry date for accuracy.

- Examine all critical areas, such as:

5.2 Intermediate Review

- Verification of In-Process Checks:

- Verify that in-process control results are documented at specified intervals and are within acceptable limits.

- Review deviations, if any, to ensure proper documentation, investigation, and approval.

- Quality Control (QC) Results:

- Check for QC testing data to verify that it meets the product specifications.

- Review all analytical and microbial test results for each finished batch, including stability testing results if applicable.

- Documentation Compliance:

- Ensure that all entries in the batch record are initialed, dated, and legible.

- Verify that corrections, if any, are done according to the company’s documentation standards, with explanations provided for changes.

- Handling Deviations and Discrepancies:

- Investigate any deviations documented in the batch record and ensure appropriate corrective and preventive actions (CAPA) were applied.

- Document all discrepancies and actions taken to address them.

5.3 Final Batch Record Review and Approval

- Final Documentation Review:

- Conduct a final review to confirm that all sections of the batch record are complete, legible, and verified.

- Verify that the record has undergone all necessary reviews and signatures by responsible departments, including QC, Production, and QA.

- Review of Release Criteria:

- Ensure that the batch meets all quality specifications and release criteria.

- Verify that any outstanding issues have been resolved, and no open deviations or discrepancies remain.

- Approval or Rejection of Batch:

- If the batch meets all specified requirements, QA will sign off and release the batch for distribution.

- If the batch does not meet specifications, initiate a rejection process, document the reason, and notify relevant stakeholders.

- Archiving of Records:

- Batch records should be retained in the designated secure storage location.

- Ensure that records are retrievable for audits and inspections.

6. Documentation Requirements

All reviews and approvals must be documented in the batch record. The following should be included:

- Dates of each review step

- Names and signatures of personnel involved in review and approval

- Any amendments, justifications, and corrective actions undertaken

- Final disposition of the batch (approved or rejected)

7. Deviations and Non-Conformance Management

- If deviations occur, they should be documented in the batch record with a clear explanation and associated corrective and preventive actions.

- QA is responsible for evaluating the impact of the deviation on product quality and determining if a deviation report is required.

8. Training

All QA personnel involved in batch record review must be trained in GMP, documentation practices, and specific requirements for batch record review. Training should be documented and reviewed annually.

9. References

- Good Manufacturing Practice (GMP) guidelines

- Quality Assurance Policy of the facility

- SOP on Documentation Control and Review

10. Revision History

| Version | Date | Description of Change | Approved By |

|---|---|---|---|

| 1.0 | DD-MM-YYYY | Initial SOP Release | Name |

For pharmaceutical jobs, follow us on LinkedIn

For Editable SOPs in word format contact us on info@pharmaceuticalcarrier.com

For more information kindly follow us on pharmaguidelines.co.uk